400V 245 * 60mm 650W Fais Far Infrared Ceramic caij rhaub rau thermoforming

Product Description

Ceramic infrared rhaub yog tsim los ntawm ceramics.

1. Cov khoom siv hluav taws xob: qhov siab tshaj plaws ntawm cov hluav taws xob monochromatic tau mus txog 0.9, tag nrho cov hluav taws xob ib txwm muaj ntau dua 0.83.

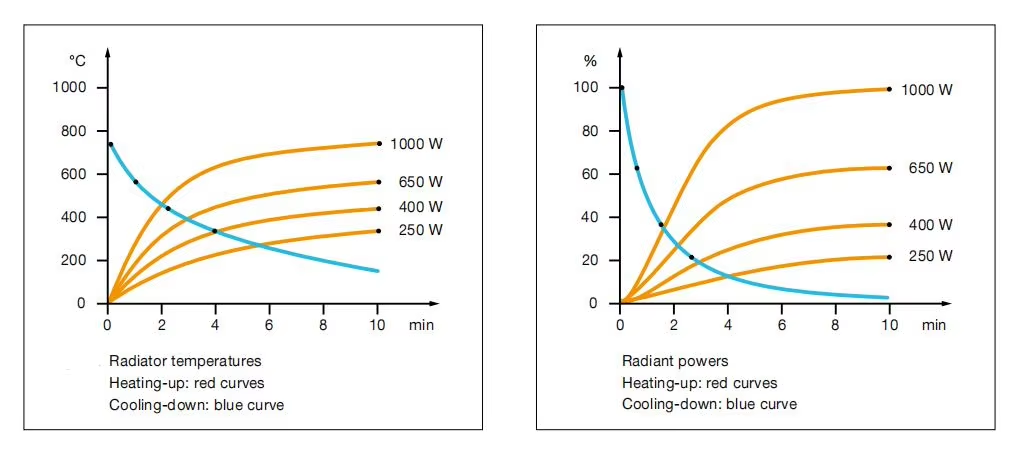

2. Thermal teb lub sij hawm: los ntawm chav tsev kub ib txwm mus rau ib tug tas mus li tus nqi ntawm lub radiant vaj huam sib luag nto kub tsawg tshaj li 20 feeb.

3. Degeneration ntawm kub thiab txias tsis kam: tsib alternating kub thiab txias kuaj ntawm tsis muaj tev, tsis muaj cracking.

Nta:

1.Kev kub siab heev, txwv ntau los ntawm qhov kub siab tshaj plaws ntawm cov emitter

2. Lub sij hawm teb ceev ceev, ntawm qhov kev txiav txim ntawm 1-2 vib nas this Kub gradients, tshwj xeeb tshaj yog nyob rau hauv cov ntaub ntawv webs nrog high kub input

3.Focused rhuab cheeb tsam txheeb ze rau conductive thiab convective cua sov txoj kev

4. Tsis sib cuag, yog li tsis cuam tshuam cov khoom raws li kev siv hluav taws xob lossis cov cua kub cua sov ua

Daim ntawv thov

1.PET ua cua sov hauv tshuab tshuab moulding tshuab

2.Printing Ink ziab hauv cov tshuab offset

3.Screen-printing curing ntawm T-shirts thiab textiles

4.Powder txheej curing

5. Roj hmab coated kom qhuav

6.Sterilizing / daim iav txheej kom qhuav hauv iav kev lag luam

7. Xim ci

8.Daim ntawv txheej kom qhuav

9.Txhua hom lamination

Preheating ua ntej embossing

Daim ntawv pov thawj thiab kev tsim nyog

Pab neeg

Kev ntim khoom thiab kev thauj mus los

Cov khoom ntim khoom

1) Ntim hauv cov rooj ntoo ntoo

2) Lub tais tuaj yeem hloov kho raws li cov neeg siv khoom xav tau

Kev thauj khoom

1) Qhia (cov qauv xaj) lossis hiav txwv (kev txiav txim ntau)

2) Kev pabcuam shipping thoob ntiaj teb