Tau txais peb daim ntawv tso cai pub dawb hnub no!

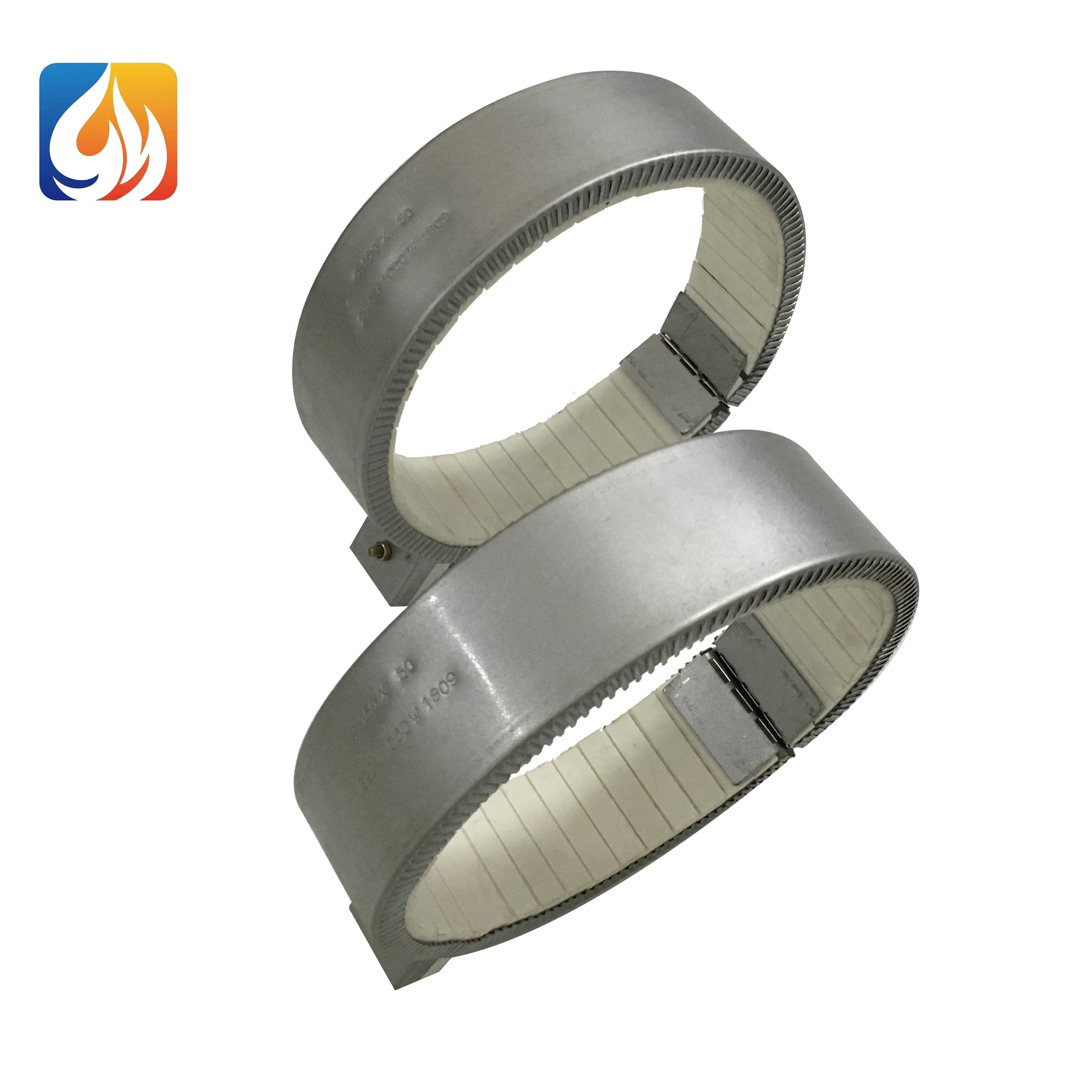

ceramic band rhaub rau spraying melting daim ntaub extruder

Product Detail

Lub extruder ceramic tag nrho kaw lub nplhaib cua sov yog ib hom hlau hlau qhov txhab nyob ib ncig ntawm lub me me ceramic square, thiab sab nraud yog qhwv hauv lub plhaub stainless hlau. Cov khoom cua sov yog ua los ntawm cov khoom siv hluav taws xob txawv teb chaws rau hauv lub caij nplooj ntoos hlav thiab muab tso rau hauv ib lub voj voog ceramic. Lub hau npog sab nrauv yog ua los ntawm cov hlau tsis muaj steel, thiab cov rwb thaiv tsev kub ntawm cov paj rwb (aluminium silicate fiber board) yog siv rau hauv nruab nrab los tiv thaiv qhov kub thiab txias. Ceramic rhaub muaj nyob rau hauv coil thiab phaj duab.

Feem ntau siv hauv cov tshuab ua cov yas, nyob ntawm daim ntawv thov, cov tshuab cua sov no tau nruab nrog lub zog txuag hluav taws xob sab nraud uas muaj kev sib xyaw ua ke zoo tshaj plaws ntawm lub cev muaj zog, siab emittance thiab thermal conductivity zoo, tuaj yeem ua kom sov cov cartridge qhov chaw, haum rau lub tsho kub txog li 500 ° C thiab lub zog txuag.

Npaj kom paub ntxiv?

Khoom ua haujlwm

Ceramic tag nrho cov cua kub lub nplhaib ntawm lub extruder tsis yog ua los ntawm cov mica winding txoj kev, tab sis los ntawm cov ceramic sawb threading txoj kev, yog li lub hwj chim ntawm cov khoom no yog 0.5-1.5 lub sij hawm siab tshaj li cov zoo tib yam.

1. Kev hloov hluav taws xob sai, cov cua sov tsis sib xws thiab kev ua haujlwm ruaj khov.

2. Qhov kub tsis tuaj yeem tawm, tuaj yeem txuag hluav taws xob, thiab ua haujlwm tau zoo.

3. Cov khoom muaj lub zog loj

4. Nickel-chromium tsis kam xaim: Nws muaj cov yam ntxwv ntawm cov cua sov tsis sib xws, qhov kub thiab txias stability, thiab lwm yam. Nws tsis oxidize rau lub sijhawm ntev thiab siv tau ntawm 200-500 ℃ rau lub sijhawm ntev.

5. Lub neej ntev, zoo thermal rwb thaiv tsev kev ua tau zoo, muaj zog txhua yam khoom, corrosion kuj, magnetic teb kuj, thiab lwm yam.

6. Txoj kev xaim tuaj yeem hloov kho raws li cov neeg siv khoom xav tau, nrog cov voltages xws li 36V, 110V, 220V, 230V, 380V, thiab lub zog load ntawm 6.5W ib square meter.

Yuav xaj li cas

Thov muab cov ntaub ntawv hauv qab no:

1.Vottage: 380V, 240V, 220V, 200V, 110V tuaj yeem kho tau.

2. Wattage: 80W, 100W, 200W, 250W tuaj yeem kho tau.

3. Loj: Ntev * dav * thickness.

4. Seb puas muaj qhov. Yog tias muaj, nws yog qhov tsim nyog los muab tus lej, qhov loj thiab qhov chaw ntawm lub qhov.

5. Thaum tshav kub kub rhiab hom: ntsaws, ntsia hlau, txhuas, thiab lwm yam.Step

6. Qhov ntau

7.Lwm cov kev cai tshwj xeeb yog tias koj muaj lawv

Ceramic pob nrog lub rhaub

1) Lub hnab yas + thawv rau siv lub tshuab cua sov

2) Ntoo lub thawv rau siv lub tshuab cua sov

Ceramic thauj nrog lub rhaub

1) Qhia (cov qauv xaj) lossis hiav txwv (kev txiav txim ntau)

2) Muab kev pabcuam shipping thoob ntiaj teb

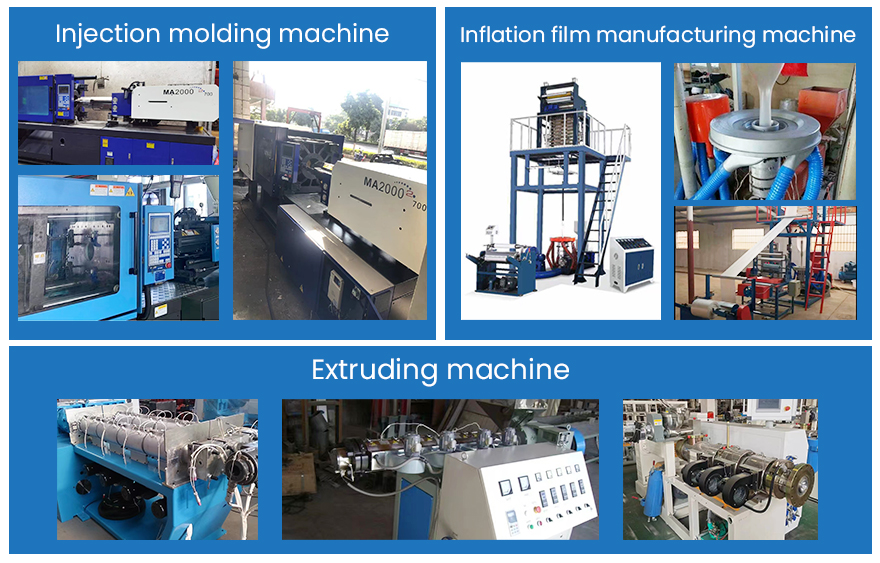

Daim ntawv thov scenario

1. Txhaj tshuaj molding / extrusion tshuab

2. Roj hmab molding / yas txheej txheem machinery

3. Pwm thiab tuag taub hau

4. Ntim machinery

5. Shoemaking tshuab

6. Cov khoom siv kuaj / kuaj cov khoom siv

7. Khoom noj khoom haus ua tshuab

8. Cov thoob nrog cov khoom khib nyiab lossis kua dej

9. Lub tshuab nqus tsev twj thiab lwm yam ...

Peb lub tuam txhab

Yan Yan Machinery yog cov chaw tsim khoom tshwj xeeb hauv cov tshuab cua sov. Piv txwv li, mica tape heater/ceramic tape heater/mica heating plate/ceramic heating plate/nanoband heater, etc. Enterprises to ywj innovation brand, tsim "me me heat technology" thiab "micro heat" khoom trademarks.

Nyob rau tib lub sijhawm, nws muaj qee yam kev tshawb fawb ywj pheej thiab kev tsim kho muaj peev xwm, thiab siv cov thev naus laus zis thev naus laus zis los tsim cov khoom siv hluav taws xob cua sov los tsim cov khoom lag luam zoo tshaj plaws rau cov neeg siv khoom.

Lub tuam txhab tau nruj raws li ISO9001 kev tswj hwm zoo rau kev tsim khoom, txhua yam khoom muaj nyob rau hauv kab nrog CE thiab ROHS cov ntawv pov thawj.

Peb lub tuam txhab tau tshaj tawm cov cuab yeej siv ntau lawm, cov cuab yeej ntsuas qhov tseeb, kev siv cov khoom zoo raw khoom; Muaj pab pawg kws tshaj lij, kev pabcuam zoo tom qab muag; Tsim thiab tsim ntau yam khoom siv hluav taws xob zoo rau kev txhaj tshuaj molding tshuab, tshuab nqus tsev, hlau nqus tshuab, tshuab moulding tshuab, extruders, roj hmab thiab yas khoom thiab lwm yam lag luam.