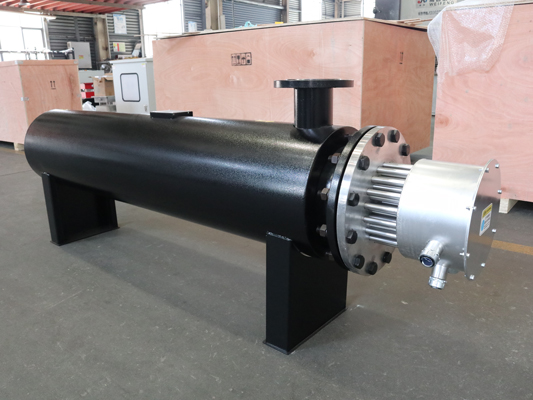

Covhluav taws xob cua sov nitrogen pipeline rhaubsystem yog ib qho cuab yeej uas hloov hluav taws xob hluav taws xob mus rau lub zog thermal kom sov cov nitrogen ntws hauv cov kav dej. Nws cov qauv tsim qauv yuav tsum coj mus rau hauv tus account cua sov efficiency, kev nyab xeeb, thiab automation tswj. Cov hauv qab no yog nws cov ntsiab lus tseem ceeb thiab cov lus piav qhia ntxaws:

1,Cua sov lub ntsiab module

1. Hluav taws xob cua sov caij

• Core cua sov Cheebtsam:

Fin hom hluav taws xob cua sov raj: ua los ntawm stainless hlau (xws li 304/316L) los yog high-temperature alloy cov ntaub ntawv, nrog nto pressed fins kom kub dissipation cheeb tsam thiab txhim kho tshav kub exchanger efficiency. Sab hauv yog ua los ntawm cov hlau tsis muaj zog (nickel chromium alloy), ntim nrog magnesium oxide hmoov (MgO) ua cov khoom siv rwb thaiv tsev thiab ua kom sov, ua kom muaj hluav taws xob rwb thaiv tsev thiab kub tsis kam (kub tsis kam tuaj yeem ncav cuag 500 ℃ lossis siab dua).

Installation txoj kev:

Covcua sov tubyog sib npaug ntawm cov kev taw qhia axial ntawm lub raj xa dej thiab tsau rau sab hauv phab ntsa lossis lub tes tsho sab nrauv ntawm lub raj xa dej los ntawm flanges lossis vuam, ua kom muaj kev sib cuag nrog cov cua sov saum npoo thaum nitrogen ntws.

Ntau cov txheej txheem cua sov tuaj yeem sib xyaw ua ke / ntu, thiab kev tswj hwm lub zog tuaj yeem ua tiav los ntawm kev tswj hwm pawg (xws li cua sov peb theem: qis, nruab nrab, thiab siab zog).

2. Pipeline lub cev

Main pipeline:

Khoom siv: Stainless hlau 304/316L (tiv taus kom qhuav nitrogen corrosion), nrog 310S lossis Inconel alloy muaj rau qhov kub thiab txias.

Structure: Seamless steel yeeb nkab vuam los yog flange kev twb kev txuas, sab hauv phab ntsa polishing kev kho mob (Ra ≤ 3.2 μ m) kom txo cov roj ntws tsis kam, cov yeeb nkab txoj kab uas hla tsim raws li nitrogen txaus tus nqi (m ³ / h) thiab ntws tshaj tawm (pom zoo 5-15m / s), ua raws li GB / T 18984.3 qauv.

• Txheej rwb thaiv tsev:

Qhwv txheej txheej nrog pob zeb wool los yog aluminium silicate fiber, nrog ib tug tuab ntawm 50-100mm, thiab npog nws nrog stainless hlau phaj kom txo tau kub (qhov kub thiab txias ≤ 50 ℃).

2,Tswj qhov system

1. Chav ntsuas kub

• Sensors:

Kev ntsuas kub: Pt100 thermistor (qhov tseeb ± 0.1 ℃) lossis K-hom thermocouple (siab kub tsis kam ≥ 1000 ℃), ntsia rau ntawm qhov nkag thiab qhov hluav taws xob ntawm cov kav dej thiab hauv nruab nrab ntawm cov cua sov, saib xyuas qhov kub ntawm lub sijhawm.

Flow/pressure sensors: vortex flowmeter, thermal mass flowmeter (paj ntsuas ntws), siab transmitter ( ntsuas qhov siab), siv los xam cov cua kub xav tau.

• Tswj:

PLC lossis DCS system: Integrated PID algorithm, hloov kho cua sov lub zog raws li qhov kub thiab txias (xws li los ntawm thyristor fais fab regulator lossis solid-state relay SSR), txhawb cov chaw taws teeb saib xyuas thiab cov ntaub ntawv kaw.

2. Hluav taws xob tswj module

• Fais fab system:

◦ Input fais fab mov: AC 380V / 220V,50 Hz,Configure circuit breakers thiab leakage protectors los pab txhawb peb-theem sib npaug zog.

Kev tswj fais fab: Cov khoom hauv lub xeev relay (SSR) los yog lub hwj chim regulator, contactless switching, ceev teb ceev, ntev lifespan.

• Cov cuab yeej tiv thaiv kev nyab xeeb:

Kev tiv thaiv overtemperature: Nruab nrog lub tshuab hluav taws xob bimetallic los yog qhov kub hloov pauv, thaum ntsuas qhov ntsuas kub siab tshaj qhov ntsuas tus nqi (xws li 20 ℃ siab tshaj qhov kub ntawm lub hom phiaj), cov cua sov fais fab raug yuam txiav tawm thiab lub tswb tshwm sim.

Kev tiv thaiv overcurrent / luv Circuit Court: tam sim no transformer + Circuit Court breaker los tiv thaiv Circuit Court abnormality tshwm sim los ntawm cua kub tube faults.

Kev tiv thaiv siab: Lub siab hloov pauv yog txuas rau kaw kom tsis txhob muaj cov kav dej ntau dhau (ua rau thaum nws tshaj 1.1 npaug ntawm qhov tsim siab).

Interlocking muaj nuj nqi: Txuas nrog nitrogen qhov chaw, cua sov yog txwv tsis pub thaum tsis muaj roj ntws kom tsis txhob qhuav hlawv.

3,Cov khoom pab cuam

1. Txuas thiab nruab cov khoom siv

Ntshuam thiab xa tawm flanges: RF ca flanges (PN10 / PN16) yog siv, nrog cov khoom siv tib yam li cov raj xa dej, thiab cov sealing gasket yog cov hlau qhwv gasket lossis PTFE gasket.

• Bracket thiab kho qhov chaw: Carbon steel galvanized lossis stainless hlau bracket, txhawb nqa kab rov tav / ntsug, nrog qhov sib txawv tsim raws li cov yeeb nkab txoj kab uas hla thiab lub peev xwm thauj khoom (xws li DN50 pipeline bracket spacing ≤ 3m).

2. Kev ntsuam xyuas thiab kev saib xyuas interface

Kub / siab ntsuas qhov sib txuas: Khaws G1 / 2 "los yog NPT1 / 2" threaded interfaces ntawm qhov nkag thiab qhov hluav taws xob ntawm cov kav dej kom yooj yim disassembly thiab calibration ntawm sensors.

• Tshem tawm qhov hluav taws xob: Lub DN20 tawm valve yog ntsia rau hauv qab ntawm lub raj xa dej kom tsis tu ncua ntawm cov dej condensed los yog impurities (yog tias nitrogen muaj cov kab dej noo).

• Kev tshuaj xyuas lub qhov: Cov kav dej ntev lossis cov qauv tsim tau nruab nrog ceev qhib tshuaj xyuas flanges kom yooj yim hloov cov kav dej cua sov thiab ntxuav cov phab ntsa sab hauv.

4,Kev nyab xeeb thiab tawg pov thawj Tsim (yog tias xav tau)

Kev ntsuas pov thawj tawg: Yog tias siv rau hauv qhov chaw tawg thiab tawg (xws li kev cob qhia petrochemical), lub kaw lus yuav tsum ua raws li Ex d IICT6 explosion-proof standard, lub raj cua sov yuav tsum yog explosion-proof (nrog explosion-proof certification for junction boxes), thiab cov khoom siv hluav taws xob yuav tsum tau muab tso rau hauv cov khoom pov thawj tawg.

Kev tiv thaiv hauv av: Tag nrho cov txheej txheem muaj kev ntseeg siab hauv av (kev tiv thaiv hauv av ≤ 4 Ω) txhawm rau tiv thaiv cov hluav taws xob zoo li qub thiab muaj kev pheej hmoo to.

5,Tej kev siv

Kev lag luam tshuaj: nitrogen purging, reactor preheating, ziab txheej txheem cua sov.

Kev lag luam Electronics: High purity nitrogen cua sov hauv semiconductor manufacturing (yuav tsum tau sab hauv phab ntsa polishing kom tsis txhob muaj kab mob).

Metallurgy / Kub Kho: Rauv inlet cua sov, hlau annealing nrog tiv thaiv cua sov.

xaus lus

Covhluav taws xob cua sov nitrogen pipeline rhaubsystem yog nyob nruab nrab ntawm hluav taws xob cua sov ntsiab lus thiab ua tiav qhov kub thiab txias nce los ntawm kev tswj ntse. Nws cov qauv yuav tsum sib npaug thermal efficiency, kev nyab xeeb, thiab kev ua kom zoo ntawm cov kua dej, ua rau nws tsim nyog rau cov xwm txheej uas xav tau qhov kub thiab txias, huv si, thiab tiv thaiv tawg. Thaum tsim, cov khoom siv, kev teeb tsa hluav taws xob, thiab cov txheej txheem tswj hwm yuav tsum raug xaiv raws li cov kev ua haujlwm tshwj xeeb (ntws tus nqi, kub, siab, ib puag ncig) kom ua haujlwm ruaj khov mus ntev.

Yog tias koj xav paub ntau ntxiv txog peb cov khoom, thovtiv tauj peb!

Lub sij hawm xa tuaj: Plaub Hlis-10-2025